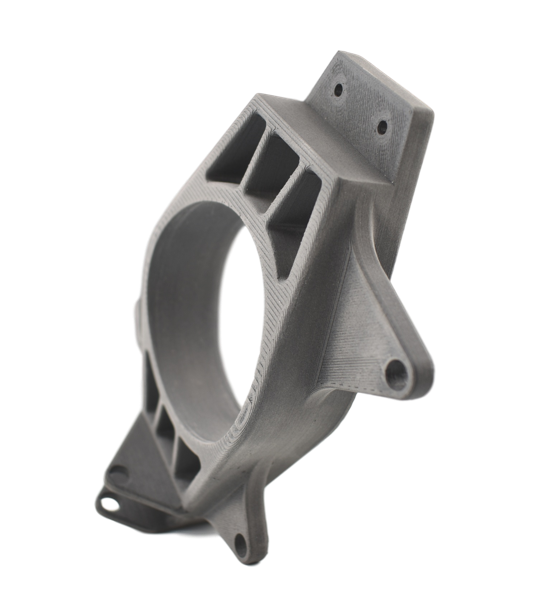

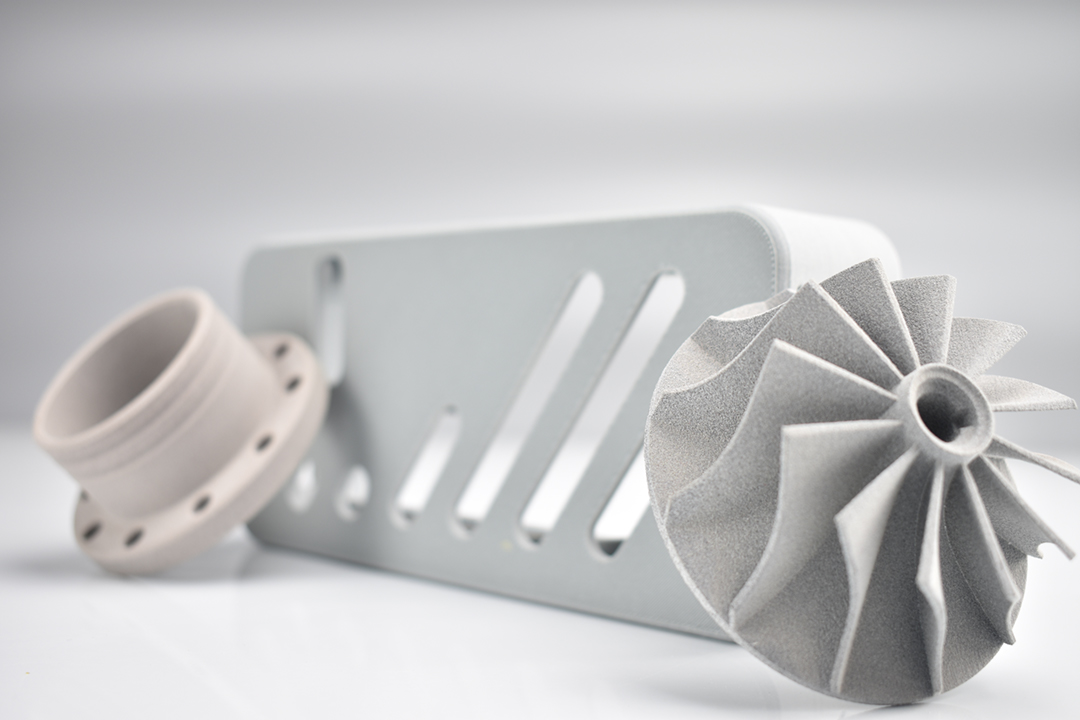

FDM 3D Printing – Technology Overview

We employ the highest quality industrial FDM printers to give you exceptional results, in time, every time.

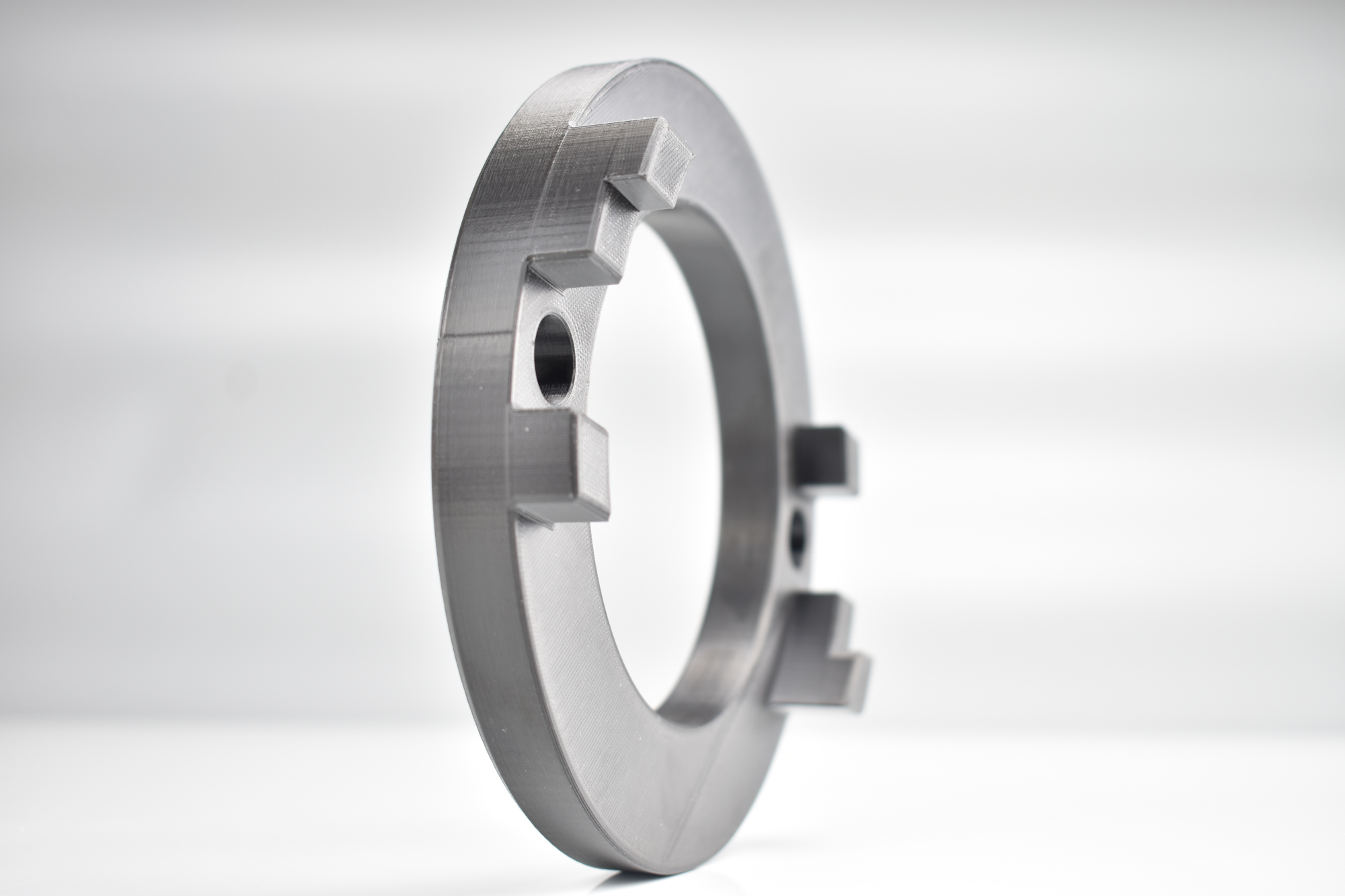

Arguably the most used 3D printing process worldwide, FDM machines deposit a thermoplastic filament through a heated nozzle onto a build plate literally “drawing” one layer at a time until the full model is completed and ready for clean-up and support removal.

The technology has enormous advantages compared to more traditional manufacturing processes:

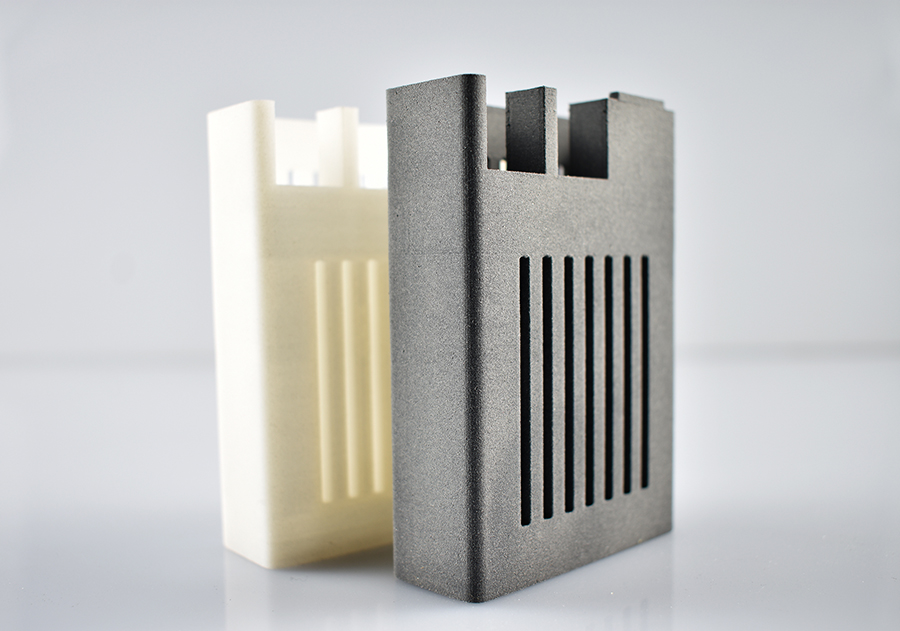

Cheaper

FDM 3D Printing has proved extremely cost-effective for one-off prototypes, iterative design and low volume batch production.

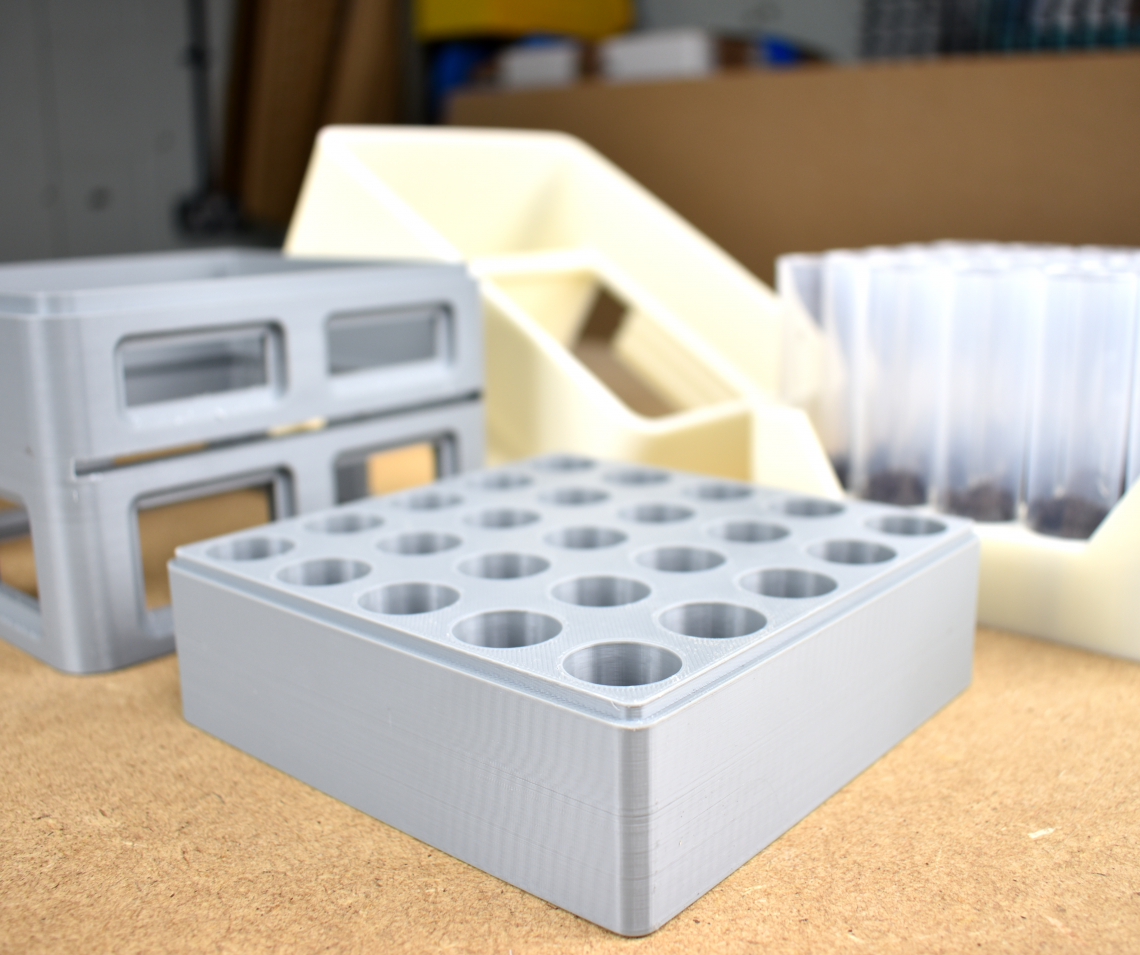

Quicker

No need to say this is where FDM 3D Printing excels, lead times for prototyping and small batch manufacturing are reduced from months to a matter of days.

Flexible

No tooling or setup costs, go straight to production and keep iterating throughout the process. Designers and engineers can now customise their products at unprecedented speed to meet and surpass their Customers’ expectations.